SFB/Transregio 150 model reduction for reaction transport systems in the exhaust system

- contact:

Overview

Motivation

Selective catalytic reduction (SCR) with urea-water solution is a process for reducing nitrogen oxide emissions from internal combustion engines. The underlying physicochemical processes, particularly those leading to the formation of solid residues, are still not understood in detail.

These processes include a variety of potentially coupled physical processes such as diffusion and convection, both in the liquid and gas phases, evaporation and chemical reactions. For this reason, detailed simulations of the entire SCR process are very complex and the demands on computing power are high. To reduce the complexity and computational cost of such simulations, there is a need for efficient and accurate reduced models that can describe both the detailed chemical processes and multiphase flow.

Aim

The aim of this project is to develop reduced kinetic models for urea and its degradation products. These are needed to reliably and efficiently describe the complex chemical kinetics in large eddy simulations (LES) of the processes in the exhaust system. For this purpose, detailed reaction mechanisms for the model system are analyzed and reduced using different mathematical reduction concepts. Reactions in all phases (gas, liquid, solid) and phase changes are taken into account.

Methods

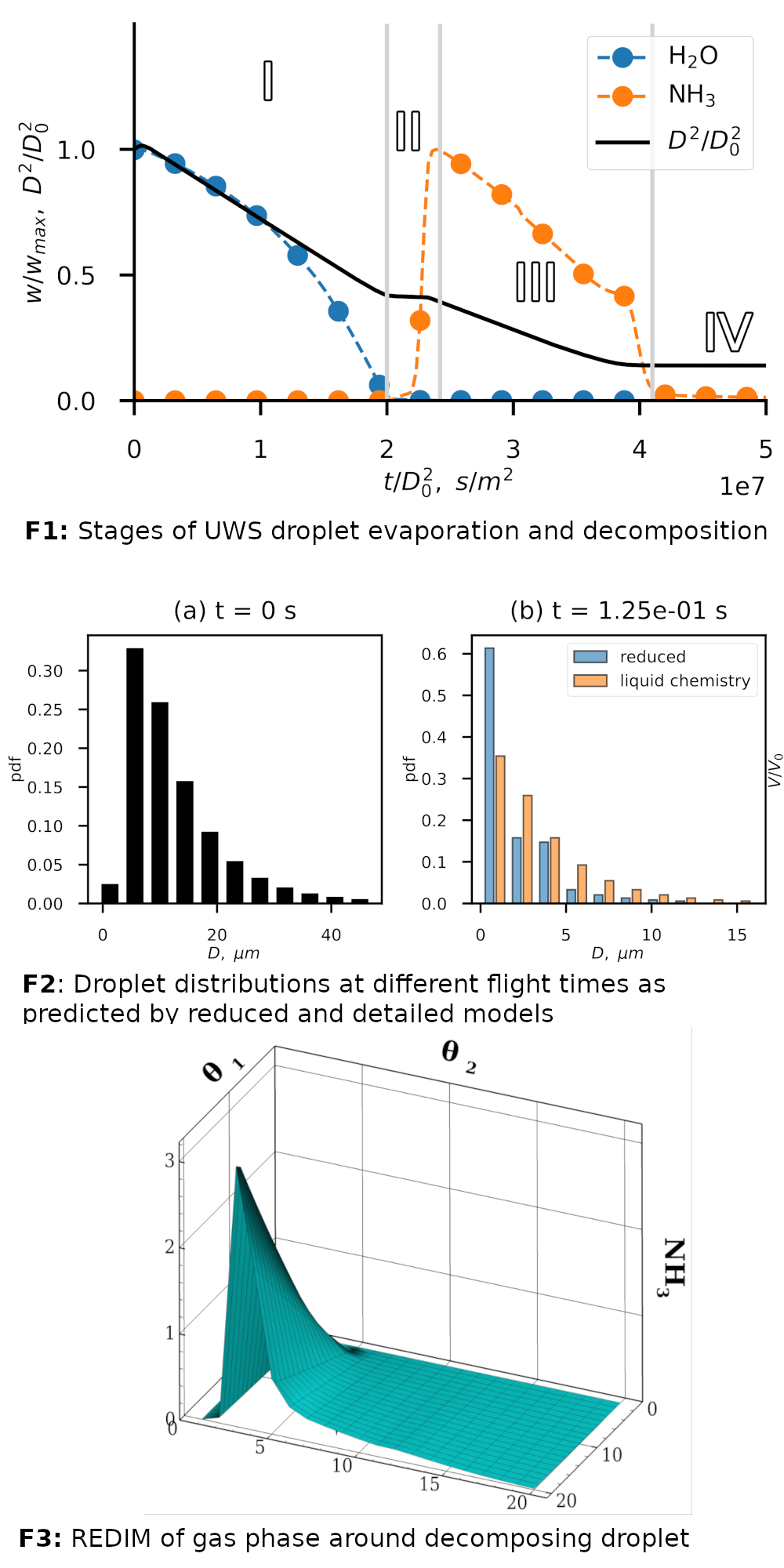

An evaporating and decomposing drop or film of a urea-water solution is used as a model system. The internally developed INSFLA program package is used to investigate detailed 1D simulations of evaporation and chemical reactions in the gas and liquid phases.

The calculated concentration profiles are analyzed based on various reduction concepts:

- Reduction concepts based on a local timescale separation, e.g. ILDM (intrinsic low-dimensional manifolds) or a global one, e.g. GQL (global quasi-linearization).

- The REDIM concept (reaction-diffusion manifolds) is used to consider the coupling of chemistry and transport.

- Processes are modeled using a modified D2-approach.

Suitable model reduction concepts are selected for different processes and reduced models are developed.

Results

Outlook

- The reduced models for different phases and processes must be coupled

- In the detailed simulation, which serves as a reference for the reduced models, additional influencing factors must be considered, such as the influence of the velocity field on droplet evaporation